- Home

- /

- News

- /

- Industry News

Synchronous & Induction Motors: Discovering the Difference

A simplistic division of fractional horsepower motors would be AC, DC, brushless, and universal.

However, just as shoes can be broken down into work boots, dress shoes, sneakers, and so on, each motor category has various subgroups. AC motors, for example, can be split into synchronous and induction (also known as asynchronous) motors.

However, just as shoes can be broken down into work boots, dress shoes, sneakers, and so on, each motor category has various subgroups. AC motors, for example, can be split into synchronous and induction (also known as asynchronous) motors.

While both function on AC power (though synchronous also uses DC), their creation, operation, and usage are quite different.

Before breaking down the two AC categories of discussion, it is important to keep in mind that in a typical AC motor, a rotating magnetic field is produced by the stator, having been induced by the input current. This field’s speed is determined by the frequency of the power supply and the number of poles of the machine and is termed, “synchronous speed”—or rather, speed that occurs simultaneously.

Induction:

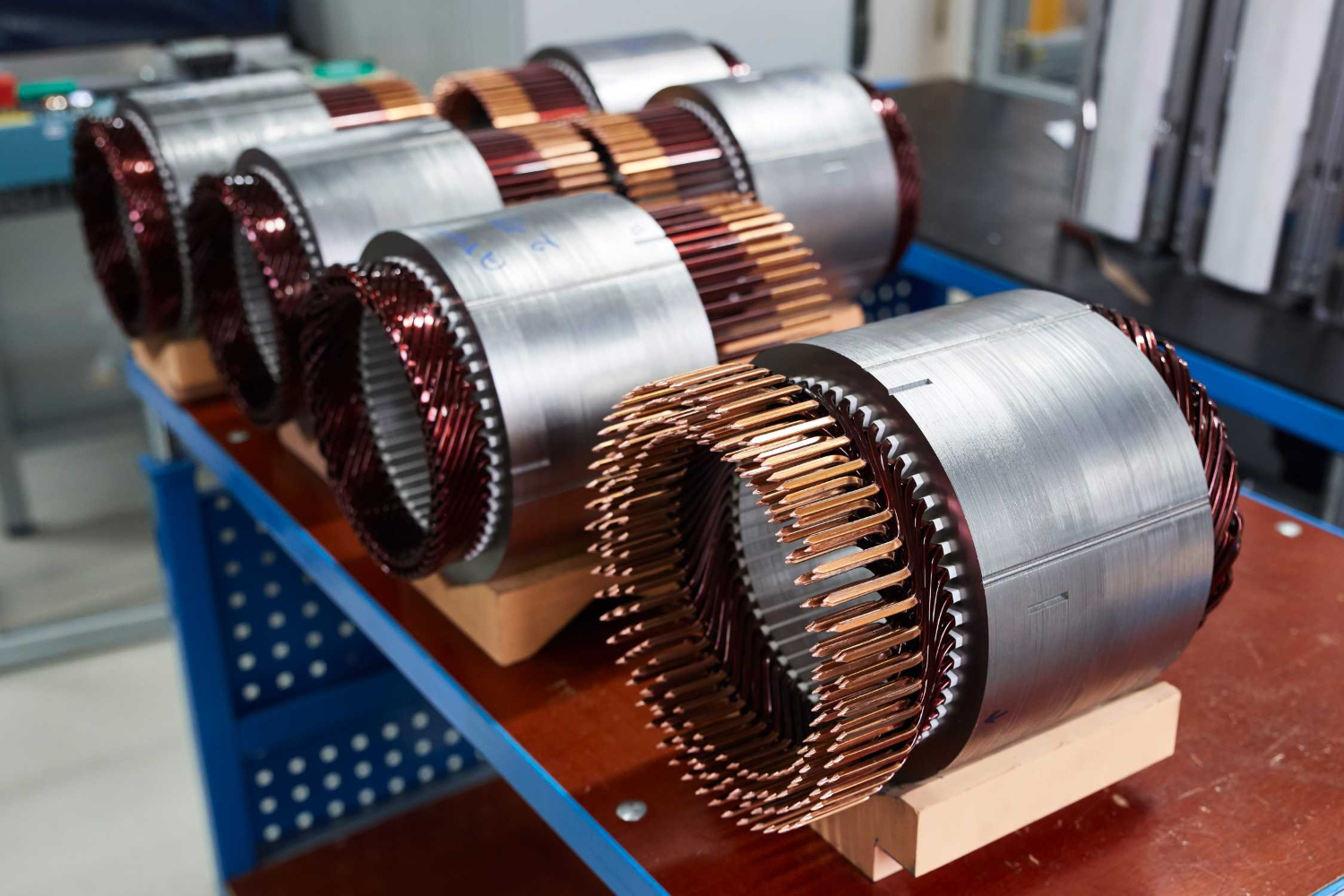

When people refer to asynchronous motors, they are generally referring to AC induction motors. The most common type, a squirrel cage AC induction motor, typically has a stationary winding called a stator, as well as a rotor that is made from electrical steel and conductive bars of aluminum or copper which are shorted on each end.

As stated above, a magnetic field is produced in the stator from the AC power, which in turn induces currents in the rotor’s conductive bars. This domino induction effect results in an attraction between the rotating magnetic field of the stator and the induced magnetic field of the rotor. A simple equation might help illustrate this more clearly.synchrounous motor, induction motor, fractional hp motors, hp manufacturer, gear motor

AC Supply + Stator = Rotating Magnetic (synchronous speed)

Rotating Magnetic + Rotor = Rotating Magnetic (lagging behind synchronous speed)

The rotor will naturally rotate slower than the synchronous speed of the magnetic field in the stator, but the attraction between the stator and rotor components places them in a continuous game of catchup (by producing torque). The difference between these two speeds is called slip and is usually given as a percentage of the synchronous speed.

Magnetic (faster) – Magnetic(slower) = Slip

Synchronous:

As you might guess, a synchronous motor has a rotor that rotates at the same rate as the synchronous speed. This is possible because synchronous motors are based on frequency and are not dependent on the consistency of the initial input current.

Think of synchronized swimmers in a diving competition. Their movements are directly in-tune with the other swim team member—their beginning, middle, and entry points are potentially identical.

Synchronous motors operate much the same way. However, just as it would’ve taken much time to work up to this level of uniformity in their diving techniques, synchronous motors don’t achieve identical rotation between the magnetic fields of the rotor and stator with the initial input current alone.

AC power induces the stator (like a typical induction motor), but then it reaches its lag point, DC power is applied via an exciter—a device that supplies a magnetizing current to the motor to create flux.

This allows rotation to increase and link up with the synchronous speed and unless acted upon by extreme conditions, these speeds will remain synced, thus allowing high precision functions to be achieved by the application in use.

This leads us to a brief summary of how the different make-up of AC motors enable each to maintain their own individual, and diverse, operation and usage.

Synchronous:

Higher initial cost

Need for an exciter

For high-precision applications (like a clock or turntable)

Most efficient in large industrial motor applications

Dependent on frequency (more consistent)

Induction:

Potential higher lifetime cost

Special controls not typically required

More common; used in many everyday applications

Most efficient in smaller applications

Speed various on torque

As you can see, induction and synchronous motors, while both classified as AC, have some rather diverse constructional and operational characteristics, with the presence of slip being the most prominent factor. Because of this, induction motors are typically unable to maintain a constant speed under variable load torque applications.

Synchronous motors best serve their purpose in larger applications, whereas Dolin specializes in fractional horsepower motors, which typically don’t require synchronous motor attributes.

However, if the consistency of synchronous is what is desired, this disadvantage of AC induction motors can be overcome using a variable frequency drive (VFD) or a vector drive.

Newer articles

- How to select a motor for an industrial application (27/02/2018)

- Why do we combine a servo motor with a gearbox (05/03/2018)

- When and Why You Should Choose a Worm Gear Reducer (06/03/2018)

- What are the advantages and disadvantages of the induction motor ? (21/02/2018)

- Select the right motor for your hydraulic applications (27/02/2018)

- Why Are Gear Reduction Starters Replacing Direct Drive Starters? (19/02/2018)

- Advantages and disadvantages of different types of gears (01/09/2018)

- How to Select a Gearmotors (01/10/2019)

- AC Motor Manufacturing Process Flow (Electric Motors) (18/02/2018)

- What are Brushless DC Motors (31/05/2019)

Older articles

- Gearbox Motors vs Integrated Gearmotors (16/04/2008)

- AC or DC? brushed DC or brushless DC Gear Motor? (24/04/2008)

- Advantages And Disadvantages of Induction Machines (10/01/2018)

- The Dangers of Deference (01/01/2018)

- How to Select a Gearbox Supplier (11/01/2018)

- Right Angle Speed Reducers Explained (01/01/2018)

- Everything You Need to Know About Gear Reducers (17/02/2018)

- Harsh Environment IP-66 Motors & Gearmotors (17/02/2018)

- Three Phase Induction Motors (17/02/2018)

- Factors to Consider When You Buy an Electric Motor (17/02/2018)

Join